The Only Guide for Motorcycle Parts New Zealand Specialists

Table of ContentsLittle Known Questions About Motorcycle Parts New Zealand Specialists.Top Guidelines Of Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Can Be Fun For EveryoneMotorcycle Parts New Zealand Specialists Can Be Fun For EveryoneOur Motorcycle Parts New Zealand Specialists DiariesNot known Details About Motorcycle Parts New Zealand Specialists Motorcycle Parts New Zealand Specialists for BeginnersNot known Facts About Motorcycle Parts New Zealand Specialists

Get to out to one of our professionals today.CNC machining innovation is promptly ending up being the focal factor of various manufacturing procedures around the globe as a direct result of its lots of benefits over other approaches. Furthermore, the sectors that make motorbikes have actually jumped on board with this fad. The most cutting-edge business are now creating their engine components and wheels utilizing machining techniques initially created for motorbike parts.

You might be wondering why we make use of. Now that we have your attention let us describe the reasoning behind this modern development in the bike manufacturing industry.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

In enhancement, you have total control over the appearance of the elements, even down to the min information. Occasionally, motorcyclists might decide to spruce up their trip by mounting aftermarket elements or changing the bike's makeover.

All About Motorcycle Parts New Zealand Specialists

CNC machining may be utilized to make almost all of a motorbike's metal and plastic elements. To proceed, we'll talk about a number of machined parts for bikes.

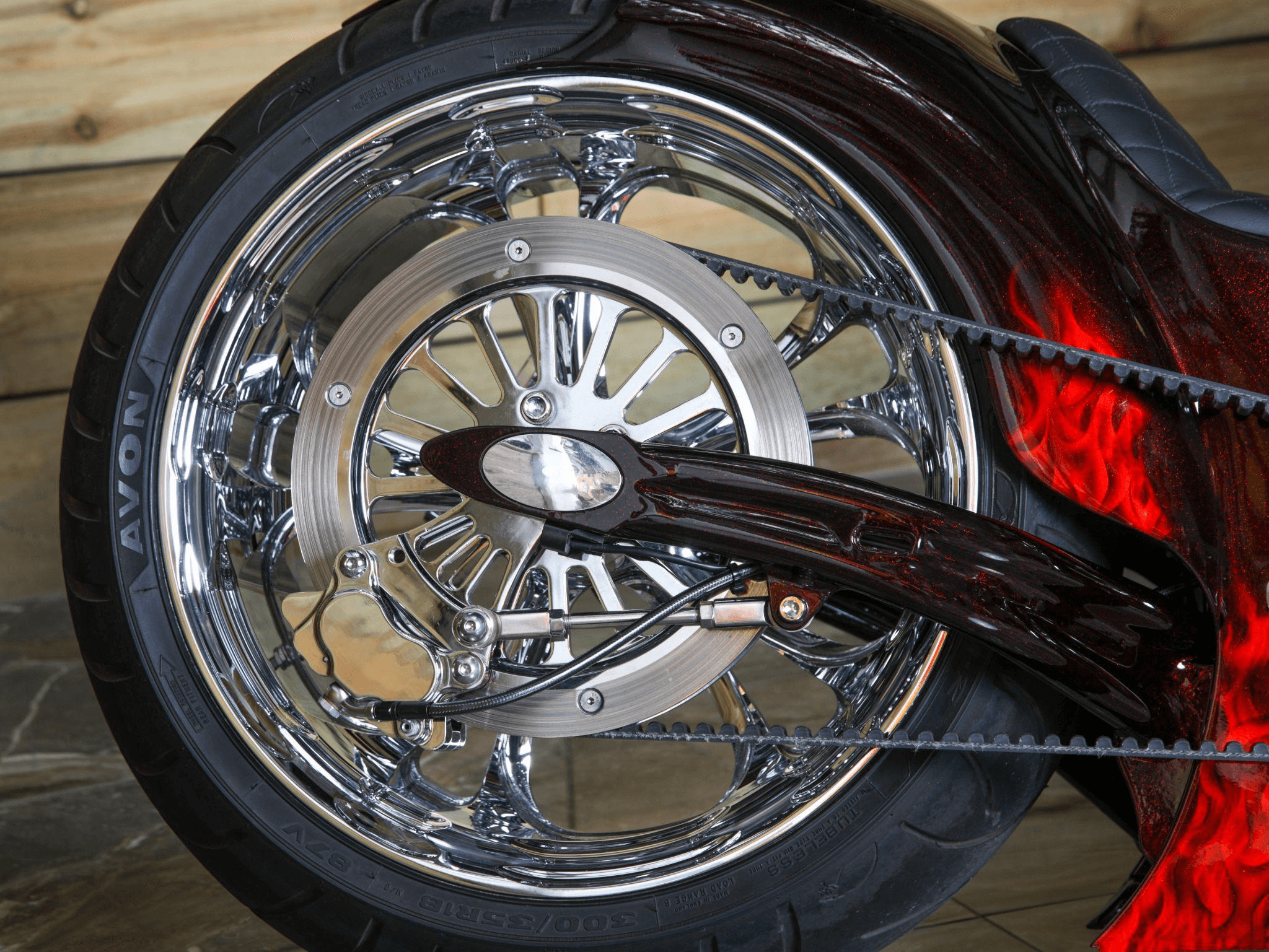

When customizing the wheels, the disks are where the emphasis needs to be. Most of them are constructed out of light weight aluminum. Aluminum alloys are widely known for the exceptional machining capacities that they have. Milling procedures are made use of to get the preferred level of wheel modification. One more facet of the motorbike that might be customized is the tires.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

When it pertains to an automobile (or a motorbike), one of the most important component is the engine. Numerous individuals mention it as the "heart" of the vehicle. On the various other hand, the camshaft, the cyndrical tube head, and the pistons often tend to be elaborate and need designs with a high degree of precision.

Usage only premium things, nonetheless, since these lights are essential for the safety and security of motorcyclists and other motorists or individuals on the roadway, especially at night. Bike fronts lights have three major components: the light bulb, or light source, the lens, and the real estate.

Milling processes with a flawless finish would certainly result in the lenses having a reflective top quality that resembles that of a mirror. The cover, on the various other hand, is not composed of delicate products; instead, it is constructed out of difficult polymers that can be machined right into more complex patterns.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

They typically have elaborate geometries with a wide range of minute information. Bike suppliers commonly cast these parts, but only for the production of bespoke parts. Nonetheless, CNC machining is the approach of selection when generating one-of-a-kind pieces. Machining on 5 axes in today's globe is the methods by which any type of design shape may be recognized.

Pick Runsom for your personalized motorbike components! We have the capability to fabricate complex and trendy parts making your motorbike incomparable.

Right here are a few instances of metals usually made use of in bike element machining. Light weight aluminum is the main product utilized by business concentrating on producing custom-made motorbike components to create a lot of these parts. In the past, we would certainly construct our engines out of actors iron. On the other hand, aluminum is rapidly next page becoming the material of option, partially as a result of the fact that it is more lightweight.

Zinc refers to one more metal that is really light in weight and has great machining top qualities due to its high mechanical toughness. This material might be developed right into nearly any form and keeps its dimensions well. Also mission-critical elements that need a high level of precision may gain from their usage.

The 7-Second Trick For Motorcycle Parts New Zealand Specialists

Another steel that sees hefty use in the manufacturing of CNC-customized components is magnesium. It is amongst the lightest steels that are now obtainable and has exceptional machinability functions and strength commensurate with its reduced weight. Among the drawbacks of magnesium is that its dirt may conveniently catch fire.

Their click to find out more most usual usage in creating various bike parts is fasteners, such as screws and bolts. Their low susceptibility to oxidation and rust makes them ideal for this usage.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

It seems that CNC transforming and grating are the fundamental processes. In addition, it calls for maintaining bars of product, most typically plastic or metal, in position and then twisting a reducing tool to eliminate areas of the material as the material is turned.

These methods are equally crucial and produce parts with high precision and regular high quality. The processes help boost the total high quality of the machined bike parts.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists